-

RG7 measures the level by transmitting radar pulses towards the object and receiving its echoes. The level is determined by the pulses travel time that is proportional to the distance between the sensor and the object surface.

MEASURING PRINCIPLE

Upon reception, the microprocessor that runs the intelligent software in the sensor head analyzes the echoes, transforms them into the surface level values, and outputs the data. Since the radar pulses are minimally affected by the tank content and its environment like temperature and pressure, radar measurement is proven to be the most reliable gauging method in most applications.

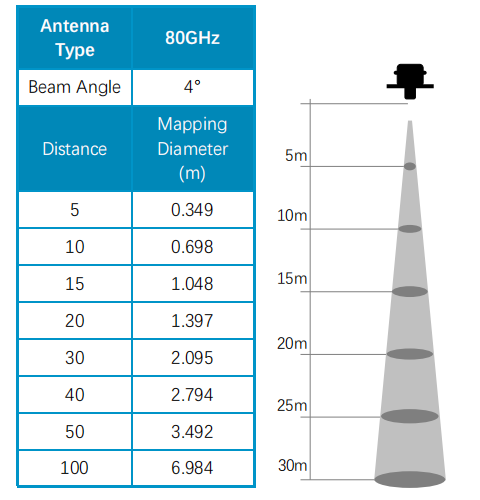

BEAM ANGLE

Additionally, because the radar sensor is not physically contacting with the measured object, maintenance of the sensor is extremely minimal.

-

APPLICATIONS

RG7 is very capable of measuring both calm surface liquids such as storage and buffer tanks as well as very uneven, disturbed surface liquids such as reactor tanks. It is applicable over a wide range of industrial applications including:

* Chemical and petrochemical

* Refinery

* Pharmacy

* Food and beverage

* River intake gate

* Process in waterworks

* Water reservoir

* Waste water treatment plant

* Hydraulic power station

* River and dam

* Coolant pit in steel process

FEATURES & BENEFITS

* 80GHz high frequency radar, can be measured even in low permittivity medium

* The antenna is small and easy to install

* Non-contact measuring

* No moving parts

* High accuracy: ±1mm

* Small beam cone angle, only 4° for improved energy concentration. Well-suited for narrow spaces with minimal interferences

* Very small “dead” zone, accurate measurement of low tank levels

* Less affected from foam, steam, dust and other potential interferences

* High reliability, Simple maintenance

* High signal-to-noise ratio, excellent performance even under extreme surface fluctuations

* Integral with display and keypad

* Two wire loop-powered, 4-20mA analogue output with Hart for standard model

-

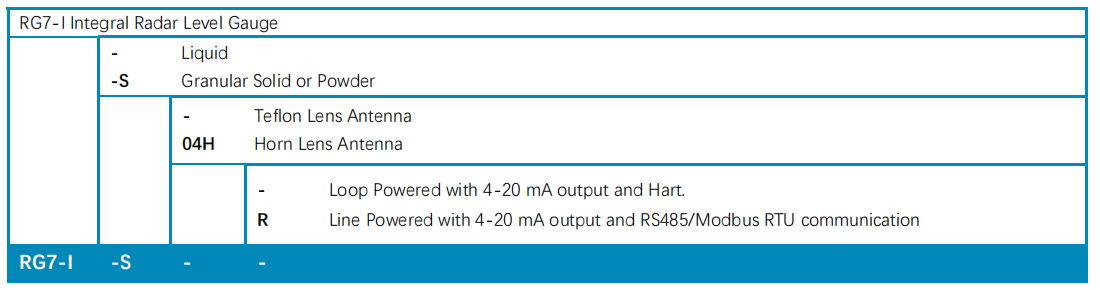

Selection Guide