-

MEASURING PRINCIPLE

AIM4000 is an extractive, continuous dust monitor utilizing forward laser light scattering principle.

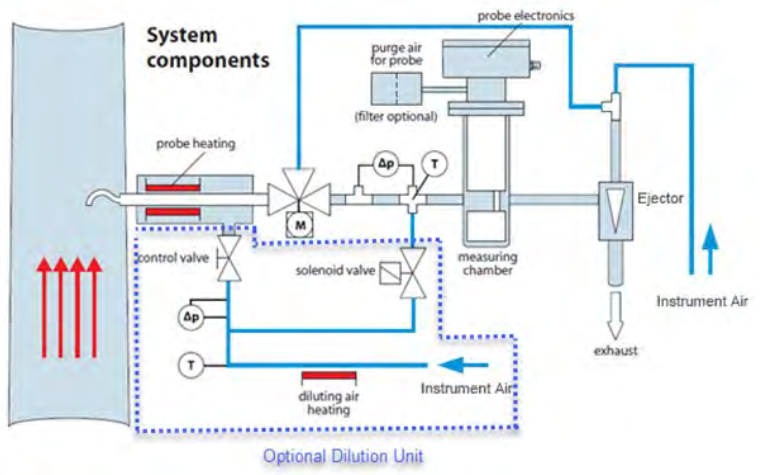

This single side installed system consists of four major components:

sampling and returning unit,

constant speed tracking and control unit,

heating and temperature control unit,

measurement and signal processing unit.An embedded ejector where the fluid flow is generated by clean, particle free gas. Typically, this gas is instrument air.

The air flow generates to the sample inlet anegative pressure, which draws the sample into the measuring chamber and then returns to the stack/process continuously.

To meet EPA’s regulation, the sampling probe usually comes with an optional pitot tube flow sensor which is used to control the sampling speed according to the velocity of the stack gases.

The highly stable laser light source emits a laser beam into the measuring chamber.

The forward scattered light from the particulate matter is collected by a precision lens and optical fiber assembly into a sensitive photoelectric detector.

The photoelectric signal is transformed into an electrical signal proportional to the concentration of particulate matter.

The lenses are kept clean by air curtains formed by purging air.

An optional dilution unit is recommended for higher range applications where the particle-containing gas flows continuously heated and diluted with clean, air directly into the sampling probe.

This immediately lowers the relative moisture, evaporating residual moisture in the heated probe.

-

FEATURES & BENEFITS

■ Compact design

■ Very low maintenance requirement

■ In-situ measuring method with continuous measurement

■ High sensitivity

■ No laborious device adjustment.

APPLICATIONS

■ The AIM4000 is used for measuring dust concentration in duct/stack gases.

■ Potential applications e.g.:

■ Measurements in saturated gas downstream of desulfurization plants

■ Downstream of wet cleaning plants

■ Waste incineration plants

■ Technological processes