-

PG7 Pressure Gauge employs a small profile, piezoresistive silicon pressure sensor packaged in a 316L stainless steel housing with 1/4” NPT threaded fittings.

The package utilizes silicon oil to transfer pressure from a stainless steel diaphragm to the sensing element.

A ceramic substrate contains laser-trimmed resistors for temperature compensation and offset correction.

The PG7 series sensors are flexible in power supply and outputs, customers can choose line-powered sensor with RS485/Modbus communication , or loop-powered sensor/transmitter with 4 to 20 mA output and Hart protocol. And providing a simple, reliable , cost-saving process data.

It offers remote monitoring, calibration, configuration and diagnostics capabilities. It is housed in a robust IP69 enclosure, connected by an 1000N tensile strength cable , providing up to 1.2km digital data transmission, ideally used in water/wastewater industries.

Specifications

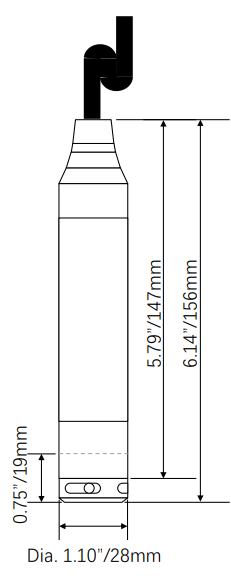

Dimension

Range

Gauge Pressure: 0 to 100 MPa Max. 0 to 5 kPa Min.

Absolute Pressure: 0 to 3.5 MPa Max. 0 to 10 kPa Min.

Differential Pressure: 0 to 3.5 MPa Max. 0 to 10 kPa Min.

Level: 0 to 300 m

Accuracy

±0.2% Optional higher accuracies down to ±0.02%, consult factory.

Repeatability

±0.025% FS

Stability

0.1% FS/Year

Temp. Drift

0.03% FS/°C

Respond Time

1s

Overload

2 times of range

Burst

3 times of range

Temp. Sensor

Pt100

Operate Temp.

-40 °C to 85 °C, instantaneous 130 °C

Temp. Accuracy

±1% °C

Storage Temp.

-40 °C to 85 °C

Power & Output

8 to 36 VDC line-powered sensor with RS485/Modbus RTU

8 to 36 VDC Loop-Powered sensor/transmitter, 4 to 20 mA output with Hart

Humidity

0 to 100%RH

Process Connection

Flange or Screw Thread

Waterproof

IP69

- ◆ High performance core elements

- ◆ Pressure and liquid level measurements

- ◆ Robust IP69/IP69K submersible enclosure

- ◆ Ultra low power consumption

- ◆ Optional Loop-powered sensor/transmitter with 4 to 20mA output and Hart protocol

- ◆ 1 second online response time

- ◆ High reliability, drift free

- ◆ 4000VDC surge protection

- ◆ Standard line-powered sensor with RS485/Modbus RTU Protocol, easy to connect with Delta-Phase's GDC (General Display & Controller) or user's terminals.

- ◆ Delta-Phase ViewTM Software is good for sensor configuration/calibration and datalogging

-

PG7 Pressure & Static Pressure Level Gauge

- (Default) Remote Sensor, line-powered with RS485/Modbus RTU, no display

-R Remote Sensor and transmitter with display, Loop Powered, 4-20mA output

-I Integral transmitter with display (No Cable). Loop Powered, 4-20mA output

G Gauge Pressure

A Absolute Pressure

D Differential Pressure

Gauge Pressure: 0 to 100 MPa Max. 0 to 5 kPa Min.

Absolute Pressure: 0 to 3.5 MPa Max. 0 to 10 kPa Min.

Differential Pressure: 0 to 3.5 MPa Max. 0 to 10 kPa Min.

Level: 0 to 300 m

Cable For Remote model

-C10 10‘ Remote Cable

-C30 30‘ Remote Cable

-C50 50‘ Remote Cable

For other lengths contact factory

PG7

-R

A

(0~10m)

-C30