-

Introduction

Delta-Phase incorporates various electrodes into CS7 sensors to widely cover conductivity measurements including most water & wastewater and chemical solutions in municipal and industrial processes. These conductivity electrodes are popular for many applications due to their convenience, affordability, and accuracy. The CS7 sensors are ideal for both portable handheld and stationery in-situ applications, offering quick time response, minimal flow dependence and low power consumption. The CS7 sensors come with different mounting types such as immersion, flow-cell and insertion /retractive ball-valve assembly installations.

Principle of Electrochemical

Conductivity is the ability of a medium to conduct electric current. The principle by which instruments measures solution conductivity is simple - two plates are placed into the sample; a potential is applied across the plates and the current is measured. Generally, the potential is in the form of a sine wave. Conductivity is determined from the voltage and current values according to Ohm's Law

G=1/R=I(amps)/E(volts)

Since the charge on the ions in solution facilitates the conductance of electrical current, the conductivity of a solution is proportional to its ion concentration.

The basic unit of measurement for conductivity is the siemens (S). Since cell geometry affects conductivity values, standardized measurements are expressed in specific conductivity units (S/cm) and compensates for variations in electrode dimensions. Conductivity measurements are temperature dependent.

Electromotive Force

The degree to which temperature affects conductivity varies from solution to solution and can be calculated. Choosing the correct Conductivity Sensor Design is critical to accuracy. The conductive plates or sensing elements in the simple conductivity electrode serve as sensing elements and are placed at a fixed distance apart in contact with the water sample to be measured. The distance between the sensing elements, as well as their surface area determine the electrode “cell constant”, defined as length/area. The cell constant is a critical parameter affecting the conductivity value produced by the conductivity cell and utilized by the meter/controller circuitry.

A cell constant of 1.0 will produce a conductance reading approximately equal to the solution conductivity. For solutions of low conductivity, the sensing electrodes can be larger, and/or placed closer together, reducing the distance between them and producing cell constants of 0.1 or even 0.01 in extreme cases. This will raise the conductivity reading by a factor of 10 to 100 to make low conductivity solutions easier to measure and give a better signal. At the other extreme, the sensing electrodes may be smaller, and/or placed farther apart to create cell constants of 10 more suitable for use in highly conductive solutions. Conductivity sensors should be calibrated using a standard solution before use. When selecting a standard, choose one that has the approximate conductivity of the solution to be measured. The following shows optimum conductivity ranges for different cell constants of two electrode sensors:

Cell Constant Optimum Conductivity Range 0.01 0.055~20μS 0.1 0.5~200μS 1.0 0.01~2mS 10.0 1~200mS CS7-4 four electrode sensor uses a reference voltage to compensate for any polarization or fouling of the electrode plates.

The reference voltage ensures that measurements indicate actual conductivity independent of electrode condition, resulting in higher accuracy, covering a wider range from 0.1 to 200 mS/cm.

This is very helpful to measure liquids with varying range, such as Conductivity, TDS and Salinity measurements of surface water including sea water.

Unlike contacting sensors, there are no wetted metal parts for Toroidal/Inductive sensors.

The CS7-T toroidal/inductive sensor determines the conductivity by using the induction between two toroidal shaped magnets embedded in the probe.

These are often better suited for higher conductivity process fluids (up to 1000 mS or even 2000 mS), especially harsh applications, for instance, to measure the concentration of Acid or Alkali solution.

-

APPLICATIONS

Water Treatment

■ Monitoring Source/Process/Dispensing Networks

■ Reverse osmosis - TDS testing

■ Desalination - Salinity testing

Waste Water Treatment Monitoring Influent/Process/Effluent, etc.

Typical Industrial Applications

■ Boiler blowdown

■ Cooling Tower

■ Rinse baths

■ Concentration of Acid or Alkali solution

■ Level DetectionFEATURES & BENEFITS

Robust Conductivity/TDS/Salinity & Temp. Sensors.

Digital sensor with reliable RS485 communication.

Plug and play with GDC series terminals or computers with Delta-Phase ViewTM software.

Calibration history data stored in sensor, Easy to recalibrate.

Lightning and surge protection for worry-free power.

Optional Self-Diagnosis function.

Contacting sensors of 2-electrodes or 4-electrodes, different cell constants are available to cover wide measuring range.

Non-contacting Toroidal (Inductive) sensors for high range applications. .

-

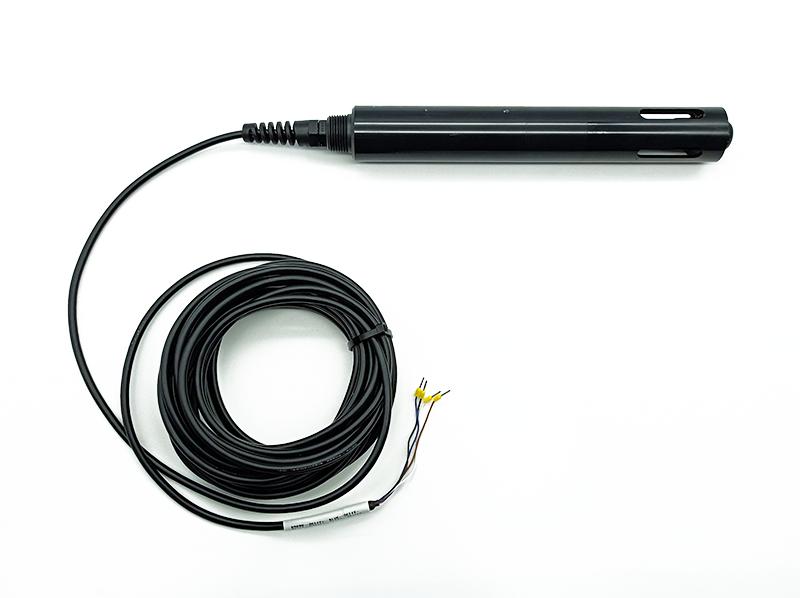

CS7 Smart Conductivity Sensor

Measuring Range & Parameters

- Conductivity 0 to 2mS, (Cell Constant 1)

-S Conductivity 0.055 to 20μS (Cell Constant 0.01)

-L Conductivity 0.5 to 200μS Cell Constant 0.1)

-H Conductivity 1 to 200mS Cell Constant 10)

-4 Four Electrodes, 0.1 to 100mS, Including TDS & SLT measurements

-TDS Total Dissolved Solid 0 to 70ppt

-SLT Salinity 5 to 60g/kg

-T Toroidal Sensor 100mS to 2000mS

Mounting (Not suitable for Toroidal sensor)

- 3/4” NPT Back Thread for Immersion mounting of rebuildable sensors

-N0 1.5” NPT Compress Fitting for rebuildable sensors flow-cell mounting

-N1 1” NPT compress Fitting for rebuildable sensors inserting installation

-N2 3/4” NPT Compress Fitting for disposal sensors (Immersion/Insertion Mounting)

-R0 Rebuildable sensors inserting with 1-1/4” NPT Retractive Ball-valve Assembly

-R1 Disposal sensor inserting with 1” NPT Retractive Ball-valve Assembly

Material of Housing

- Standard PVC

-SS 316L Stainless Steel

-PP PP

Other housing material contact factory

Length of Housing

- Standard

X17 17” (Min. length for Retractive Ball-valve Assembly Mounting)

X21 21”

Other Lengths available as optional

Length of Cable

-C10 10” Cable

-C30 30” Cable

-C50 50” Cable

Other Lengths available as optional

CS7

-L

-R0

-PP

X17

-C30